Concurrent Engineering Tools And Technologies For Mechanical System Design

What is concurrent engineering

Concurrent engineering is a method of designing and developing engineering products, in which different departments work on the different stages of engineering product development simultaneously. If managed well, it helps to increase the efficiency of product development and marketing considerably reducing the time and contributing to the reduction of the overall development cost while improving the final productquality.

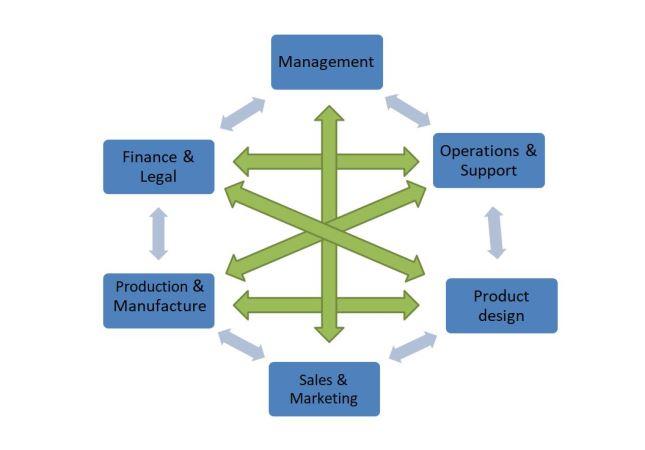

Thisstreamlined approach towards an engineering product forces several teams such asproduct design,manufacturing,production, marketing, productsupport,finance, etc., within the organisation to work simultaneously on new product development. (figure1)

For instance, while engineering product designers begin to design the product, the sales team can start working on the marketing and the product support department can start thinking about the after-sale support. While the mechanical designers work on the packaging design to incorporate the PCB being developed by the electrical engineering team, the software engineers can start looking at the software code.

Concurrent engineering, also known as theintegrated product development (IPD) orsimultaneous engineering was introduced a few decades ago to eliminate the issues from sequential engineering or so-called "over the wall" process. This systematic approach is intended to force all the stakeholders to be involved and the full engineering product cycle to be considered from concept to after-sale support. There are plenty of incentives to choose Concurrent engineering over sequential engineering product development.

The popularity ofintegrated product development has been growing recently, thanks to the ever-increasing demand for quality products expeditiously at affordable prices.

Although managing asimultaneous engineering process is very challenging, the techniques and practices followed as part of concurrent engineering benefits from several competitive advantages to the company and to the final engineering product itself.

Elements of concurrent engineering

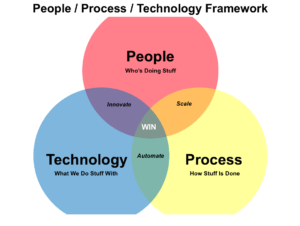

Concurrent engineering presents an environment which encourages and improves the interaction of different disciplines and departments towards a single goal of satisfying an engineering product requirements. Key elements of concurrent engineering can be summarised using a PPT framework or the Golden Triangle (Figure 2).

People, process, and technology are crucial to any organisation and essential in implementing concurrent engineering to achieve shorter development time, lower cost, improved product quality and to fulfil customer needs.

People

Concurrent product development is a multidisciplinary team task and it's necessary that companies utilise the right skilled personnel at the right time to accelerate product development. It is also necessary to find people with the right skills and experience along with the following key aspects;

- Multidisciplinary team to suit the product at the start of the NPD

- Teamwork culture at the core of the program

- Good communication and collaboration between teams – sharing relevant and up to date information across departments and personnel

- The harmonized goal across the company from the top management to the bottom of the organizational structure

Process

A process is a series of product development steps that need to happen to achieve a goal. These can be project planning stages, milestone management, problem-solving methodologies, product development key stages, information sharing workflow, etc., as just people are ineffective without processes in place to support their tasks and decisions. Following are some of the processes that can be adopted in concurrent engineering;

- Project planning processes and workflow management which include key new product development elements such as key design stages, milestones for cross-departmental interaction, etc.

- Workflow for product data management such as sharing information, manage engineering change, control specification creep, etc.

- Product requirement tracking and checkpoints using techniques such as Quality Function Deployment (QFD) across departments

- Design evaluation workflow processes

- Design analysis methodologies such as brainstorming

- Failure Mode and Effects Analysis (FMEA) allows for a systematic investigation of the occurrence and impact of possible flaws in the new product design

- The use of Design of Experiments (DOE) enables the systematic identification of critical product/process parameters that influence performance

Technology

For concurrent engineering to be successful, the effective introduction of tools, techniques, and technologies to aid asmooth integration of people and processes is vital. Following key aspects should be considered before any implementation.

- Identifying the correct tools and technologies that suit the company size, number of team members, processes implemented and product type

- Identifying the training needs and training people to use the tools and technologies identified above

These are just few of the many supportive tools that can be used in a concurrent engineering environment.

- Project management software

- Product data management & product lifecycle management suites

- Quality Function Deployment (QFD)

- 3D CAD and rapid prototyping technologies such as additive manufacturing

- Suitable FEA tools

- Evaluation tools such as DFM, DFA, DFMA and DOE

- Failure mode analysis tools such as FMEA

Concurrent new product development

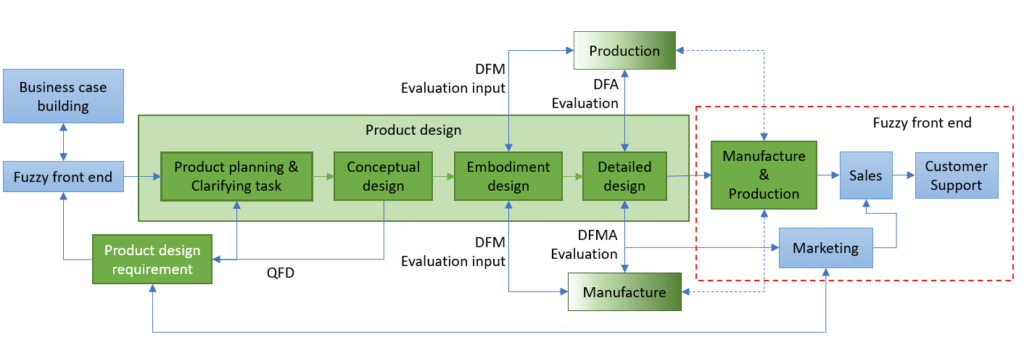

By concurrently engaging in multiple aspects of design and development phases across the PPT framework, a new product cycle can be decreased significantly. Figure 3 shows a typical new product development cycle with some examples of concurrent activities and functions discussed above.

Examples of concurrent new product development activities:

- Management consults experts from different disciplines to jointly define a product design specification (PDS). Tools such as QFD can be used to track the product requirement across departments during the initial product development stages.

- During the embodiment design stage, manufacturing is consulted to evaluate the manufacturability of the design by using tools such as DFM, QFD and DFMA.

- Production is consulted to evaluate the design for assembly, which would flag up issues with an assembly including the requirement of tools and jigs. Tools such as design for assembly (DFA) can be used to analyse the design.

- Sharing design information with production at the detailed design stages of the process would enable them to get the tools and production jigs ready for production.

- At the final stages of the design, the design team shares information such as final specification with sales and marketing teams enabling them to prepare datasheets, brochures, package design, promotional events, etc.

- Sharing the latest information across the team in a controlled central manner is crucial at all stages.

Advantages and disadvantages of Concurrent engineering

Advantages of concurrent engineering

- It encourages multi-disciplinary collaboration

- Reduces product cycle time

- Reduces cost

- Increases quality by supporting the entire project cycle – enhanced quality

- Increases productivity by stopping mistakes in their tracks

- Gives a competitive edge over the competitors

Disadvantages of concurrent engineering

- Complex to manage

- Relies on everyone working together hence communication is critical

- Room for mistakes is small as it impacts all the departments or disciplines involved

Summary

Concurrent engineering is a powerful workflow methodology if implemented correctly that will positively impact product quality and the objectives of the company. However, there are no one-size-fits-all method or procedures as each company and product development will be different. Hence, catering and putting a suitable system in place across the PPT framework is crucial to the success and a challenge faced by product managers.

Concurrent Engineering Tools And Technologies For Mechanical System Design

Source: https://engineeringproductdesign.com/knowledge-base/concurrent-engineering/

Posted by: pimenteldident.blogspot.com

0 Response to "Concurrent Engineering Tools And Technologies For Mechanical System Design"

Post a Comment